Plug. Play. Predict.

Condition monitoring can be expensive. Which is why up to 95% of all machines inside factories are only sporadically monitored, or often not at all. This can lead to unplanned breakdowns and downtime.

OPTIME from Schaeffler allows for comprehensive condition monitoring that is both easy and affordable. Thanks to its simple plug & play installation, OPTIME allows you to start monitoring hundreds of rotating machines in just a few hours.

With the ability to work on almost all machines, OPTIME can detect potential damage, imbalances or misalignments – even weeks in advance! This enables you to easily and conveniently plan your long-term maintenance, manpower or spare-parts requirements

OPTIME is now available in Indonesia!

Schaeffler OPTIME receives the “Red Dot Award“ 2021

The Red Dot Award: Product Design honours the best products each year. Whether aesthetically pleasing, functional, smart or innovative – the objects receiving the award are united by their outstanding design quality.

As of this year, Schaeffler joins the list of “Red Dot Award” winners – which includes leading companies worldwide – for its innovative condition monitoring system OPTIME.

In the “Smart Product” and “Industrial Equipment” categories, the jury consisting of designers, professors and journalists from various specialist areas chose OPTIME to receive the award. OPTIME receiving the award in two categories is testament to the exceptional quality of the product.

BENEFITS

Your key benefits at a glance

Highly cost-efficient monitoring

Monitoring hundreds of rotating machines for a few cents each per day – up to 50% cheaper than handheld measurement

Installs quickly

Installing the sensors and setting up the OPTIME app takes mere minutes – no prior experience required

Expert know-how

Digital Service provides professional diagnostics based on expert algorithms and machine learning, available 24/7 via app – so you’ll always make the right decision

For beginners & experienced users

With its intuitive operation, OPTIME provides crucial information and comprehensive expandability – perfect for a broad range of users and applications

FUNCTION

This is how OPTIME works

Plug.

The vibration sensors are attached to each machine using screws or adhesive. Then they are activated via NFC.

All sensors automatically connect to each other and the gateway. Together they form a mesh network, which is among the most reliable and energy-efficient IoT networks available today.

The system can be expanded with additional sensors at any time.

Play.

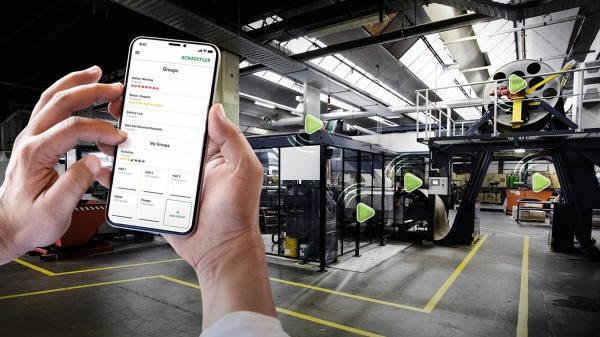

The app displays trends and, using a multi-stage warning system, provides a visual representation of the severity of potential incidents. In an emergency, it can sound an alarm and present additional information.

Exceptionally intuitive in its operation, the app offers a comprehensive array of tools that make it the perfect solution for everyone – from beginners to experts.Depending on the user’s requirements, the monitored machines can be organized into groups. The machines’ operational status can then be displayed in a variety of user-specific formats.

Predict.

The system detects malfunctions weeks in advance and provides information on the root causes. This works with continuous automatic analyses based on Schaeffler’s extensive rolling bearing expertise, know-how in condition monitoring as well as machine learning algorithms. This way, OPTIME can make planning maintenance work, identifying manpower requirements, and procuring spare parts quick, easy and cost-effective.

The system in action:

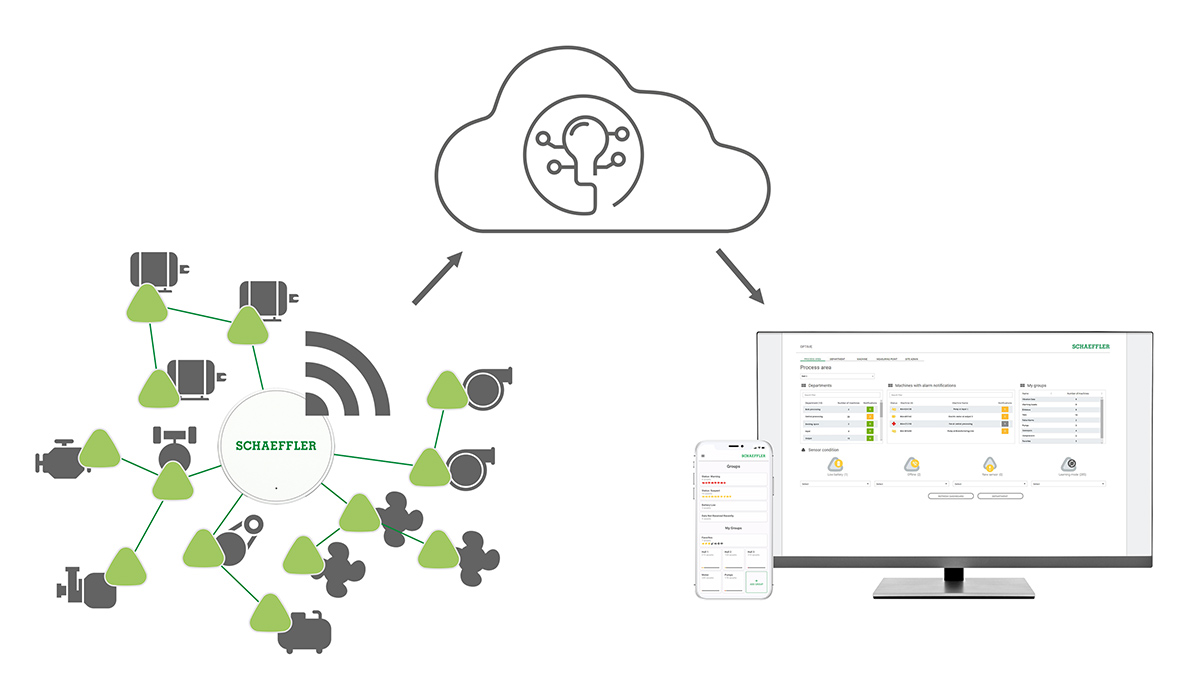

The OPTIME system consists of three components:

- Wireless, battery-powered vibration and temperature sensors that are attached to the machines to monitor their condition. Remarkably quick and easy installation means hundreds of machines can be equipped with sensors in just a few hours.

- A gateway that receives the data from the sensors. The sensors and gateway connect autonomously to form a mesh network, and the gateway transmits the data straight into the cloud – without having to be integrated into the customer’s network.

- A digital service that analyzes the data using proprietary algorithms that draw upon Schaeffler’s extensive technical expertise. The service then supplies you with intuitive diagnostic reports – via an app on your desktop or mobile device – that help you schedule your maintenance activities.